Products List

Can Making Machinery

Quality is the most important value for Sanyu.

We have installed over 2,000 machines for 50 years and many of them have still been running for decades. Each of our machines has the world class productivity but also outstanding durability.

Our machines are designed and built by our long experienced engineers and craftmen in Japan. They have strong prides on their works and are very confident with our machines before shipments.

We believe that even by using the same drawings, this Japan made quality can never been achieved elsewhere but by Sanyu Japan.

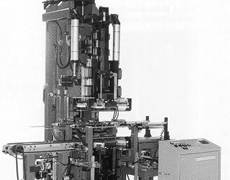

Welder

| Welder for square can |

Weld the edges of bending-formed can body |

|

| Welder for round can |

Weld the edges of round cans (202~603D, pail cans, 18L cans) |

|

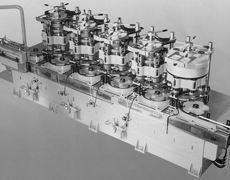

Seamer

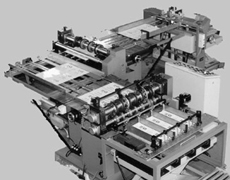

| Seamer for square can |

Seam the square can body and ends (40c.p.m, 60c.p.m) |

|

| Seamer for round can |

Seam the round can body and ends (low~high speed) |

|

Oven

| Vertical Oven |

Dry the rubber (1lane or 2 lane) |

|

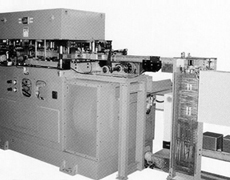

| Hurricane Oven |

Flat-tunnel type oven |

|

Transfer/Conveyor System

| Transfer Robot |

Transfer system using a robot |

|

| Automatic Sheet Feeder |

Feed any type of sheets |

|

| Strip Feeder |

Feed strips to the press |

|

| Servo Feeder |

Feed strips to the press by servo driven system |

|

| Conveyors |

Conveyor system for various uses |

|

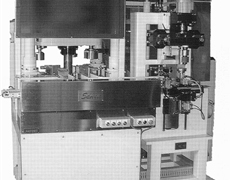

Cap Making Machinery

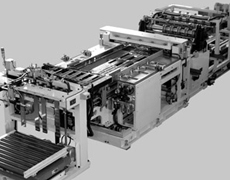

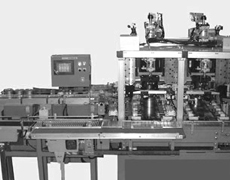

| Lug Cap Making Machine |

Complete production line for lug cap |

|

| Screw Cap Making Machine |

Complete production line for screw cap |

|

| Royal Cap Making Machine |

Complete production line for royal cap. Zigzag press,Draw.curling press,Packing set machine,Image capture device,Transfer robot |

|

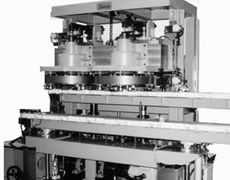

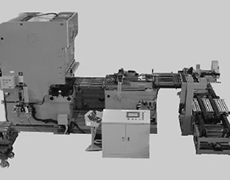

| "Mountain Top" Making Press |

Make "Mountain top" ends via 8 processe |

|

Inspection System

| Image Capture System |

Detect cracks or dust via imaging. |

|

| Orientating Inspection Device |

Detect the welded position and orient the can. |

|

| Seaming Inspection system |

Evaluate the seaming condition by displaying a cross section image |

|

| Leak Tester |

Inspect for leaks by air, vacuum or light system |

|

Pail Can Making Machinery

| Automatic Stacker |

Can stacking |

|

| Palletizer |

Put the cans onto the pallet |

|

| Packaging Machine |

Package stacked cans into bags |

|

| Orientating Device |

Detect the welded position and orientate the can |

|

| Outside Repair System |

Repair the outside welded area of the can by spray coating |

|

| Inside Spraying System |

Repair the whole of inside of the can by spray coating |

|

| Hurricane Oven |

Flat-tunnel type oven |

|

| Lining/Curling Machine |

Spray the compound to ends and process the curling |

|

| Transfer Press |

Make top/bottom ends |

|

| Cleaning Machine |

Remove the inside dust before seaming |

|

Caser ・ Palletizer

| Palletizer |

Stack the cans onto the pallet |

|

| Caser |

Case cans into a box using a robot |

|

| Banding Machine |

Band a specified number of cans |

|

| Packaging Machine |

Package stacked cans into bags to prevent collection of dust |

|

Innovative Container

| Insecticide-Can |

Recyclable container after use |

|

| Powdered milk can |

Unification of top-end and ring |

|

| Mountain Top |

Screw top like a plastic bottle |

|

| Reshaped Can |

Various reshaped cans |

|

| Cleaning Machine |

Remove the inside dust before seaming |

|